Against the backdrop of the rapid development of industrial automation, three-phase asynchronous variable-frequency motors have become standard equipment in many enterprises. It is a three-phase asynchronous motor that uses variable-frequency technology to adjust the speed. By changing the frequency of the power supply to the motor’s stator, it alters the synchronous speed and thus achieves the speed regulation function. This type of variable frequency drive induction motor has the advantages of simple structure, convenient manufacturing, easy maintenance, good performance and reliable operation, and is widely used in the industrial field.

In the following text, the working principle, product features, application fields, and selection points of three-phase asynchronous variable-frequency motors will be systematically introduced, which will facilitate the technicians, equipment purchasers, and operation and maintenance managers who read this article to quickly grasp the key points of variable-frequency transformation.

Working Principle

A variable frequency motor consists of three components: the motor body, the variable frequency drive for motor(VFD), and sensing/monitoring devices for feedback and protection.

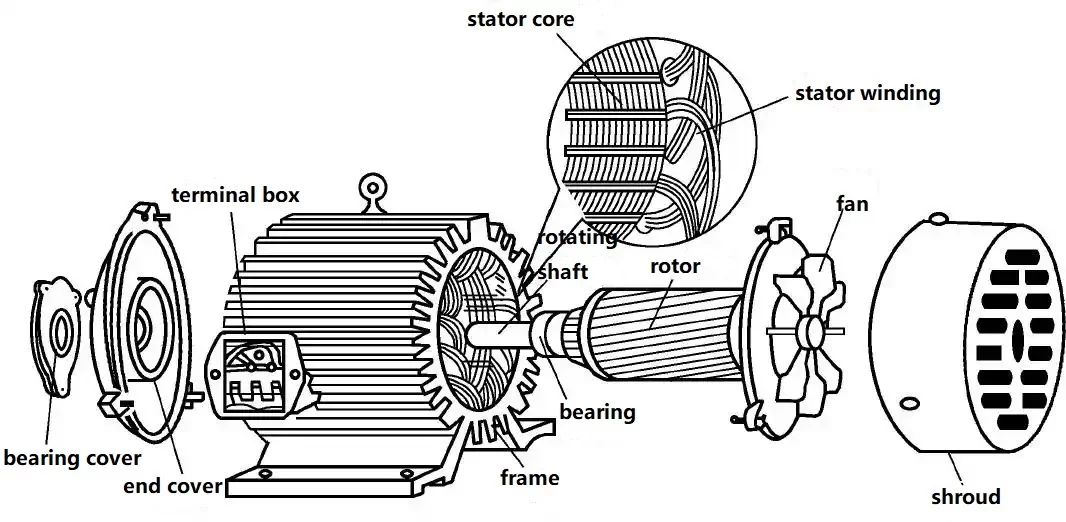

- Three-Phase Induction Motor: The structure of a three-phase induction motor primarily consists of two major components: the stator and the rotor. The structure of a three-phase induction motor is illustrated below. The rotor is mounted within the stator cavity, with an air gap between the stator and rotor. The stator section mainly comprises the stator core, stator windings, and the frame. The rotor primarily consists of the rotor core, rotor windings, and the rotor shaft. The entire rotor is supported by end covers and bearings. The primary function of the rotor is to generate induced currents, forming electromagnetic torque to achieve the conversion of electrical energy into mechanical energy. Based on the structure of the rotor windings, asynchronous motors are classified into two types: squirrel-cage rotors and wound rotors. The operating principle of a three-phase asynchronous motor is as follows: The closed windings within the rotor generate an induced electromotive force or current under the influence of a rotating magnetic field. When energized, the rotor windings produce a rotating torque in response to the rotating magnetic field, causing the rotor to rotate in the direction of the magnetic field’s rotation. The rotor’s rotational speed is lower than that of the rotating magnetic field.

- The frequency converter transforms fixed-frequency utility power into three-phase AC with adjustable frequency and amplitude. By altering the power supply frequency, it controls motor speed to achieve precise torque and power output.

- Voltage-frequency conversion speed control: Adjusts motor speed by modifying the supply voltage. The converter modulates output voltage frequency and amplitude based on control signals to match motor speed with the required speed.

- Frequency-based speed control: Adjusts the motor’s supply frequency to regulate speed. For example, converting the input voltage frequency from 50Hz to 30Hz reduces motor speed to 60% of the original.

By altering the input frequency and voltage supplied to the motor, the VFD enables smooth speed control, overcoming the limitations of traditional asynchronous motor speed regulation.

- To achieve precise speed regulation, variable frequency drive systems for 3-phase motors typically employ closed-loop control. This method involves installing position sensors, such as encoders, on the motor shaft to feed back the actual rotational speed to the variable frequency drive motor control system. The control system then adjusts the inverter’s output based on the error between the set speed and the actual speed, bringing the actual speed closer to the set speed. This ensures the accuracy and stability of speed regulation.

Product Features

- Resistance to Mechanical Vibration and Impact: Reinforced motor structure to withstand mechanical vibrations and impacts encountered during crane operation.

- Higher Thermal Insulation Rating: Incorporates a higher thermal insulation rating to accommodate heat generated during operation.

- Frequent Starting, Stopping, and Reversing: Designed to withstand the effects of frequent starting, stopping, and reversing operations required for crane motors.

- Rotor design: To minimize inertia during starts and stops, rotors are typically designed with a slender profile, reducing start-up time and minimizing start-up losses.

- Protective covers and sealed design: To withstand dusty working environments, the motor’s protective housing and sealed construction are key features.

Application Fields

Due to their flexible speed regulation capabilities and adaptability to diverse operating conditions, three-phase asynchronous variable-frequency motors are widely applied across multiple sectors and industries, including but not limited to:

- Pump and Fan Applications: Equipment such as water pumps and centrifugal fans achieve precise speed control through variable frequency regulation, saving energy and enabling smooth starts.

- Compressors and Air Handling Equipment: Adjusting speed according to load demands in air compressors, refrigeration compressors, and similar equipment to enhance energy efficiency.

- Conveying Equipment: Precise control via variable frequency speed regulation for conveyors, elevators, etc., preventing excessive impact and damage to materials.

- Machine Tools and Equipment: Providing accurate machining control to improve processing quality and efficiency.

Selection Criteria

Here we focus on selecting variable frequency motors for metallurgical hoisting applications.

- Motor power. Comprehensive consideration must be given to various forces during lifting and operation. For hoisting mechanisms, power is determined based on maximum load capacity and lifting speed. Travel mechanisms require consideration of travel speed, track friction, and potential gradient resistance.

- Motor Speed. Speed must align with operational requirements. Different work phases in metallurgical lifting equipment demand varying speeds: lifting mechanisms require low, stable speeds for precise hoisting, while traveling mechanisms select speeds based on distance and time constraints. Additionally, consider the motor’s speed regulation range, which should match actual operational speed variations to ensure stable operation across all speeds.

- Motor Duty Cycle. Metallurgical lifting equipment operates in complex environments with diverse working patterns, typically under intermittent cyclic duty or short-time duty. Under intermittent cyclic duty, the motor undergoes frequent starts, stops, and braking. This demands robust overload capacity and heat dissipation performance to withstand repeated load fluctuations. Short-time duty implies the motor must withstand significant loads for brief periods, necessitating the ability to deliver sufficient power without overheating or damage.

- Motor protection rating. Metallurgical and lifting environments are harsh, potentially containing dust, moisture, and corrosive gases. Protection ratings are generally denoted by “IP” followed by a number, with higher numbers indicating better protection.

- Motor cooling methods. Common cooling methods include self-cooling, air cooling, and water cooling. For smaller power ratings or relatively low ambient temperatures, self-cooling or air cooling may suffice. However, for high-power motors or those operating in high-temperature environments, water cooling provides more efficient heat dissipation, ensuring stable motor performance.

- Motor insulation class. Different insulation classes correspond to different permissible operating temperature ranges. In high-temperature metallurgical environments, motors with higher insulation classes should be selected to maintain reliable insulation performance during prolonged high-temperature operation, preventing electrical failures caused by insulation degradation.

- Motor torque characteristics. Metallurgical lifting equipment requires sufficient torque from the motor during start-up and braking. Particularly during the initial lifting of heavy loads, the motor must deliver substantial starting torque to ensure smooth hoisting. During braking, the motor’s braking torque must also meet the equipment’s rapid stopping requirements.

Why Choose Hanko Variable Frequency Motors?

Hanko Heavy Industry’s motors employ advanced design and technology to achieve maximum energy efficiency under various loads, helping you reduce operational costs. These motors undergo rigorous quality testing, delivering exceptional stability and durability for long-term operation in harsh conditions while minimizing failures and maintenance expenses. Furthermore, our motors support multiple control modes, offering superior response speed and precise operational control for diverse complex applications. We adhere to stringent environmental standards, ensuring motors deliver outstanding performance with minimal environmental impact, aligning with global green manufacturing trends. Our motors serve multiple industries and sectors. Whether for industrial manufacturing, construction, or specialized applications, they provide reliable solutions.

We are committed to delivering reliable, efficient, and scalable variable frequency motor solutions. Beyond supplying premium motors, we provide comprehensive system-level technical support: from operational condition assessment, simulation optimization, and prototype validation to on-site installation, commissioning, and long-term maintenance—forming a closed-loop service guarantee. Whether you’re planning energy efficiency retrofits, capacity expansion upgrades, or new construction projects, our engineering team will deliver actionable technical and economic solutions tailored to your actual operating conditions. We empower businesses to achieve stable, safe, and energy-efficient production goals. Please feel free to contact us anytime.