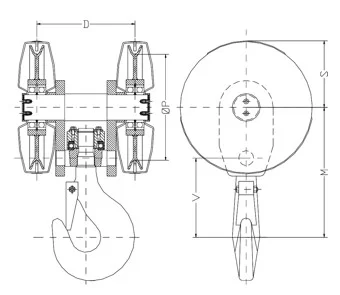

1.High-strength mobile crane hook made from forged alloy steel, offering maximum durability and load capacity.

2.Available in different mobile crane hook types, suitable for a wide range of lifting operations.

3.Equipped with mobile crane hook latch and optional mobile crane hook lock for enhanced safety.

4.Precision-engineered mobile crane hook parts ensure stable performance and long service life.

5.Tested to exceed international standards, guaranteeing safe operation even under extreme conditions.