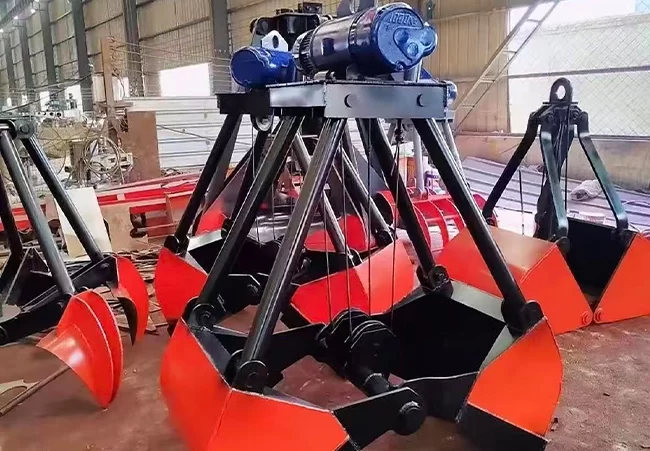

1.Independent Electric Drive, High Handling Efficiency

The electric grab bucket is equipped with a built-in motor and reduction mechanism. The opening and closing actions are directly driven by electric power, ensuring fast response and stable operation, which significantly improves loading and unloading efficiency per cycle.

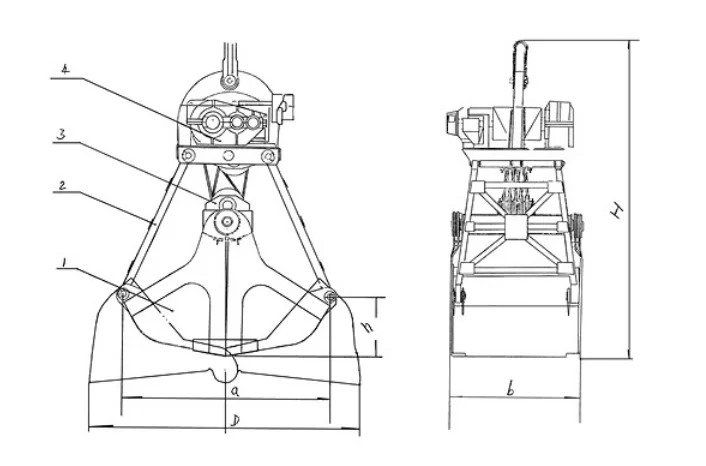

2.Compact Structure, Stable and Reliable Operation

Featuring an integrated structural design, the grab bucket has a low center of gravity and balanced load distribution, resulting in minimal vibration and high operational stability. Compared with traditional mechanical grab buckets, electric grab buckets do not rely on wire rope reeving changes, providing smoother and safer operation.

3.Strong Gripping Force, Wide Material Adaptability

With optimized transmission mechanisms and bucket shell design, the grab bucket delivers strong closing force and high filling efficiency. It is capable of reliably handling a wide range of bulk materials such as coal, ore, sand, gravel, and grain, effectively reducing material spillage and empty grabs.

4.Easy Maintenance, Low Operating Cost

The absence of complex hydraulic systems minimizes the risk of leakage and reduces maintenance requirements. Key components feature high protection ratings and excellent wear resistance, resulting in lower daily maintenance workload and reduced long-term operating costs.

The electric grab bucket utilizes an electrically driven opening and closing mechanism, enabling material handling at any height with high efficiency, strong gripping force, and stable, reliable performance. Its compact structure and ease of maintenance make it widely suitable for bulk material handling in ports, power plants, mines, and other industrial applications, serving as an ideal grabbing device for modern crane operations.