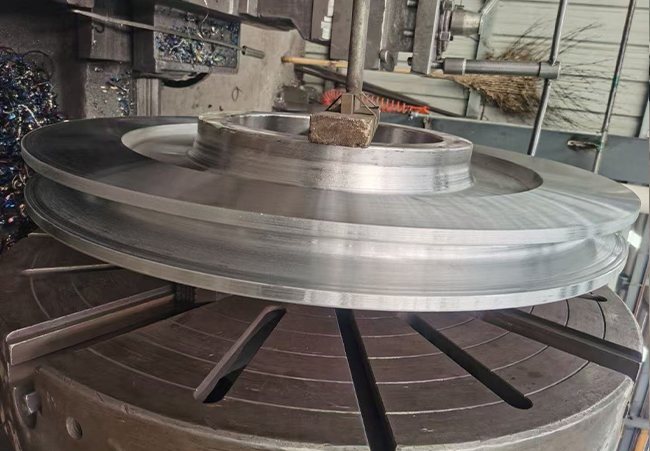

1.High Strength Design – Crane equalizer sheaves are made from forged or alloy steel, offering excellent load distribution and fatigue resistance.

2.Extended Rope Life – Precision-machined grooves reduce wear on wire ropes and improve alignment during lifting.

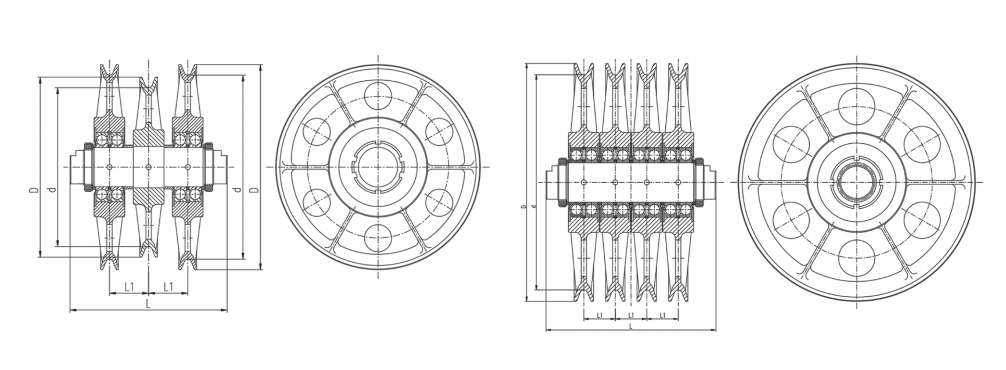

3.Versatile Application – Suitable for overhead cranes, gantry cranes, and hoist systems, with options for single and double sheaves.

Crane equalizer sheaves ensure balanced lifting, reduce rope wear, and improve overall crane efficiency, making them vital for safe and heavy-duty operations.