1.Efficient Symmetrical Clamshell Design

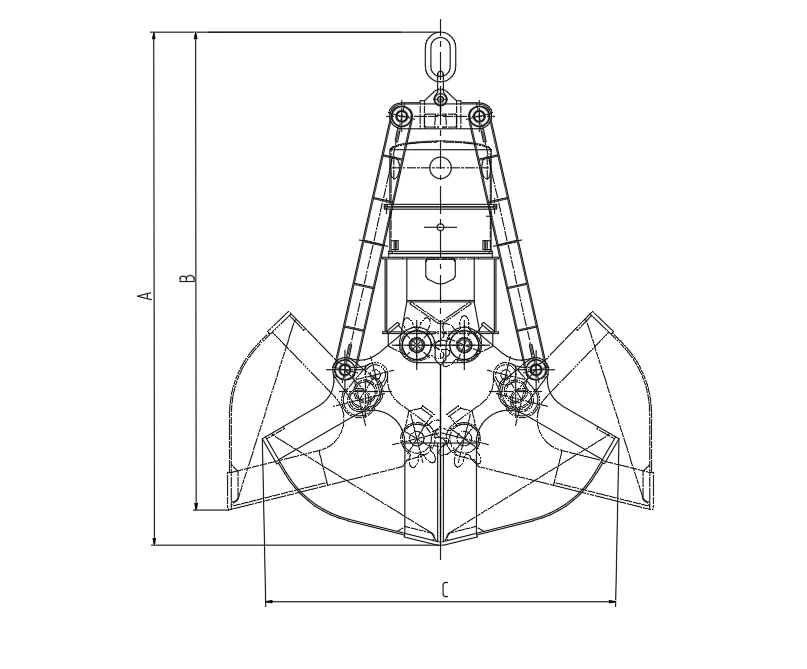

The clamshell grab features a symmetrical two-shell structure that opens and closes smoothly with balanced force distribution. This ensures stable material handling and controlled discharge, delivering reliable performance even in confined or restricted working areas.

2.High Grabbing Efficiency

The optimized shell geometry improves material penetration and filling efficiency, effectively reducing empty grabs and material spillage. As a result, the grab achieves higher single-cycle loads and significantly improves overall operating efficiency..

3.Strong and Durable Construction

Manufactured from high-strength structural steel and reinforced at critical stress points, the clamshell grab offers excellent resistance to wear, impact, and fatigue. It is well suited for continuous, heavy-duty operations..

4.Wide Compatibility and Customization

The clamshell grab can be supplied in mechanical, electric, or electro-hydraulic versions. It is compatible with overhead cranes, gantry cranes, and various port handling equipment, with customizable designs to meet specific operating conditions..

The clamshell grab is an efficient and reliable solution for bulk material handling. The balanced dual-shell design supports stable operation. The optimized structure improves filling efficiency. The durable construction extends service life. Together, these features reduce material loss and support consistent performance across a wide range of industrial applications.