In a crane’s safe operating system, the brake is truly the “guardian of safety,” bearing the critical responsibilities of motion control, deceleration and braking, and preventing load slipping. Whether it is holding and positioning a suspended load during hoisting, ensuring smooth and stable stopping of the traveling mechanisms, or providing emergency braking in the event of a sudden failure, the performance of the brake directly determines the safety and reliability of crane operation.

Functions and Design Principles of Crane Brakes

During operation, a crane must frequently perform actions such as lifting, lowering, and traveling with heavy loads, and the core function of the brake is to precisely control these movements.

Specifically, its functions are mainly reflected in three aspects. First is holding (support) braking: after a load has been lifted to the required position, the brake can reliably lock the mechanism to prevent the load from descending under the effect of gravity. This is the most fundamental and critical function of a crane brake. Second is deceleration braking: during load lowering or mechanism operation, braking torque is applied to gradually reduce the rotational speed until the mechanism comes to a smooth stop, avoiding impacts caused by inertia. Third is emergency braking: when sudden faults such as overload or loss of control occur, the brake can respond rapidly and forcibly stop the mechanism to prevent the escalation of accidents.

Based on these functions, the design of crane brakes follows the principles of safety and reliability, smooth braking, rapid response, and ease of maintenance. Among them, safety and reliability are the top priorities, requiring the brake to provide sufficient braking torque and to be automatically applied under extreme conditions such as power or air supply failure, that is, to have a fail-safe braking function. Smooth braking requires the braking torque to be adjusted steadily, avoiding impact loads during braking and thereby protecting both the crane structure and the lifted load. Rapid response means that the brake actuation delay must be kept within a reasonable range to ensure timely operation in emergency situations. Ease of maintenance is intended to reduce long-term operating and maintenance costs and to extend the service life of the brake.

Basic Components of Crane Brake System

Although crane brake system are available in various types, their basic construction is generally the same. They mainly consist of five parts: the brake frame, brake shoes, brake wheel (or brake disc), actuating device, and auxiliary devices. These components work together to perform the braking function.

The brake frame is the fundamental supporting component, used to mount the brake shoes, actuating device, and other parts, ensuring correct relative positioning of all components during braking. Its structural strength directly affects braking stability and it is usually made of cast iron or welded steel plates. The brake shoes are the core friction components; their linings must have a high coefficient of friction as well as good wear and heat resistance. Due to environmental considerations, non-asbestos friction materials have become the mainstream, and some designs allow for adjustment. The brake wheel (or brake disc) works in conjunction with the brake shoes to generate braking torque. Brake wheels are typically manufactured from No. 45 steel, while brake discs offer better heat dissipation and are more suitable for harsh operating conditions. The actuating device is the execution core of the brake and can be classified into four types: hydraulic, pneumatic, electromagnetic, and mechanical. The auxiliary devices include components for clearance adjustment, wear compensation, and limit control, ensuring normal operation of the brake and extending its service life.

Main Types of Crane Brakes

According to different braking methods, commonly used crane brakes can be classified into electro-hydraulic drum brakes, electro-hydraulic disc brakes, safety brakes, wind-proof brake.

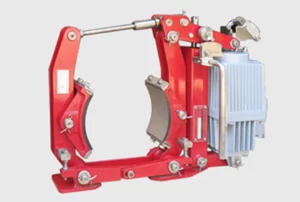

Electro-hydraulic drum brakes

The YW series electro-hydraulic drum brakes are widely used for deceleration and stopping (holding) braking of various mechanisms in crane and conveying equipment, port handling systems, metallurgical equipment, mining machinery, and construction machinery.

This series offers a wide range of models, covering specifications from YW-160 to YW-800, compatible with brake wheel diameters of 160–800 mm. The braking torque ranges from 80 to 10,000 N·m, enabling it to meet the braking requirements of different load conditions.

|

YW and YWB Series Drum Brakes |

|

| Product Model | YW(B)160-220、YW(B)200-220、YW(B)200-300、YW(B)250-220、YW(B)250-300、YW(B)250-500、YW(B)315-300、YW(B)315-500、YW(B)315-800、YW(B)400-500、YW(B)400-800、YW(B)400-1250、YW(B)500-800、YW(B)500-1250、YW(B)500-2000、YW(B)630-1250、YW(B)630-2000、YW(B)630-3000、YW(B)710-2000、YW(B)710-3000、YW(B)800-3000 |

| Brake Disc Diameter (mm) | 160、200、250、315、400、500、630、710、800 |

| Braking Torque (N·m) | 80~10000 |

Electro-hydraulic disc brakes

The YP series electro-hydraulic disc brakes are high-performance, multi-functional advanced products. Thanks to features such as automatic equalization of pad retraction clearance and automatic compensation for lining wear, they are very convenient to maintain during operation.

By adding various limit switches, the brakes can provide the necessary interlocking and protection signals to the main machine’s PLC. They are especially suitable for deceleration and holding (parking) braking of various mechanisms in modern large-scale specialized handling equipment, crane and conveying machinery, metallurgical equipment, mining equipment, and construction machinery.

| Specification | Thruster Model | Brake Disc Diameter (mm) | Maximum Braking Torque (N·m) |

| YP1 series | Ed220-50、Ed300-50、Ed500-60、Ed800-60 | 315、355、400、450、500 | 280~1750 |

| YP2 series | Ed500-60、Ed800-60、Ed1250-60、Ed2000-60、Ed3000-60 | 450、500、560、630、710 | 1000~8400 |

| YP3 series | Ed1250-80、Ed2000-80、Ed1250-60、Ed3000-80 | 630、710、800、900、1000、1250 | 3750~20000 |

Safety Brake

The SB series hydraulic safety (emergency) brakes are high-power braking devices designed for use on low-speed shafts (drum shafts). They are widely applied for emergency safety braking on the low-speed shafts of hoisting and luffing mechanisms in medium and large cranes, as well as port handling machinery.

They are also suitable for service braking and emergency safety braking of mining hoists, winches, and high-power inclined belt conveyors; safety braking of drive mechanisms for cable cars and cable cranes; and safety (emergency) braking on the low-speed shafts of hoisting mechanisms in special-purpose cranes such as casting cranes.

|

SB Series Safety Brake |

|

| Product Model | SB50、SB100、SB160、SB250、SB315、SB400、SB500 |

| Applicable Brake Disc Diameter (mm) | 500、600、1200、1800 |

| Brake Disc Thickness (mm) | 30、36、40 |

| Clamping Force F (kN)) | 50~500 |

Wind-Proof Brake

The YXZ series electric-hydraulic wind-proof wedge brake is mainly used for wind protection during operation and as auxiliary wind-prevention braking when idle for large and medium-sized outdoor cranes and port handling equipment.

|

YXZ series electric-hydraulic wind-proof wedge brake |

|

| Product Model | YXZ-250/80、YXZ-350/80、YXZ-400/80、YXZ-440/80、YXZ-500/80、YXZ-550/80、YXZ-600/80、YXZ-630/80、YXZ-700/80、YXZ-710/80、YXZ-800/80 |

| Brake Wheel Diameter (mm) | 250、350、400、440、500、550、600、630、700、710、800 |

Working Process of Crane Brakes

The operation of crane brake assembly is closely coordinated with the movements of the mechanism. Taking the hoisting mechanism as an example, the working process for crane hoist brake can be divided into four stages: lifting, hovering, lowering, and emergency braking. The control strictly follows the principle of “release brake before starting; stop first, then brake” to ensure safe operation of the equipment.

Lifting Stage: After the operator issues a lifting command, the control system first activates the brake actuator (electromagnetic coil, hydraulic station, etc.) to release the brake. Once the brake is fully released, the hoisting motor is started, which drives the load upward via the transmission shaft, wire rope, and hook. During this process, the brake remains released to ensure normal operation of the mechanism.

Hovering Stage: When the load reaches the target position, the operator issues a stop command. The control system first stops the hoisting motor. When the motor speed drops to a safe range, the power or air supply to the brake actuator is cut off. The brake, under spring force, engages to lock the transmission shaft, reliably keeping the load suspended. At this stage, the brake must withstand the full torque of the load.

Lowering Stage: Upon issuing a lowering command, the control system first releases the brake, then reverses the hoisting motor to lower the load. During this process, the control system continuously monitors motor speed and descent speed. If overspeed occurs, the system automatically adjusts the braking torque to ensure the load descends smoothly.

Emergency Braking Stage: In the event of overload, motor runaway, wire rope breakage, or other sudden faults, the control system immediately triggers emergency braking, quickly cutting off the brake actuator’s power or air supply. The brake rapidly engages under spring force, forcing the hoisting mechanism to stop. Simultaneously, safety devices such as overload limiters issue alarms to alert the operator to handle the fault.

Additionally, the control system continuously monitors the brake’s status. If issues such as failure to release, excessive brake clearance, or excessive lining wear are detected, an alarm is triggered, and operation of the mechanism is prohibited.

Key Factors Affecting the Working Performance of Crane Brakes

The working performance of crane brakes is influenced by multiple factors, primarily including braking torque, brake clearance, friction coefficient of the brake lining, heat dissipation performance, and the performance of the actuator.

Braking Torque: The braking torque must be designed according to the crane’s service class, rated lifting capacity, and operating speed, ensuring it exceeds the maximum torque of the mechanism. Insufficient braking torque can lead to brake failure, while excessive torque may cause impact during braking, damaging mechanism components. Therefore, regular inspection of the braking torque is necessary to ensure it meets the design requirements.

Brake Clearance: Brake clearance refers to the gap between the brake shoe and the brake wheel (or brake disc). Excessive clearance can cause delayed braking and insufficient torque, while too little clearance can create additional friction between the brake shoe and wheel/disc, increasing energy consumption and accelerating lining wear. Regular adjustment of brake clearance is required to maintain it within a reasonable range.

Friction Coefficient of Brake Lining: The friction coefficient is a key factor determining braking torque. A higher friction coefficient generates greater torque under the same pressure. If the friction coefficient decreases due to wear or contamination (e.g., oil, dust), braking torque will be insufficient, affecting braking performance. Therefore, the condition of brake linings should be regularly checked, and worn or contaminated linings should be replaced promptly.

Heat Dissipation Performance: During braking, friction between the brake shoe and wheel/disc generates significant heat. Poor heat dissipation can cause the brake lining to overheat and carbonize, reducing the friction coefficient and potentially leading to “thermal fade,” which compromises braking performance. Therefore, it is essential to ensure that the heat dissipation channels of the brake wheel or disc are unobstructed to prevent high-temperature-induced brake failure.

Performance of the Actuator: The actuator (such as electromagnetic coils, hydraulic stations, or pneumatic systems) directly affects the brake’s response speed and reliability. Malfunctions in the actuator (e.g., burned-out coil, insufficient hydraulic pressure, air leakage in cylinders) can prevent the brake from releasing or engaging properly, affecting crane operation. Regular inspection and timely maintenance of the actuator are necessary to ensure reliable brake operation.

In crane operations, safety comes first, and a reliable brake serves as the core barrier protecting it. Hanko Heavy Industry’s crane brakes, featuring high-strength, wear-resistant brake linings and precise transmission structures, are compatible with a full range of cranes, including bridge, gantry, and tower types, easily handling demanding conditions such as heavy-load starts and stops and high-altitude hovering. With a modular design, fast response, and stable braking torque, they effectively eliminate risks such as hook slippage and brake failure. For any inquiries, please feel free to contact us.