1.High Grabbing Force & Stable Operation

Powered by a dedicated hydraulic system, the hydraulic grab bucket delivers strong and consistent closing force, ensuring reliable material handling even under heavy-duty and high-frequency operations.

2.Excellent Material Adaptability

With optimized bucket geometry and precise hydraulic control, the grab performs efficiently when handling bulk, loose, or irregular materials such as ore, coal, scrap, sand, gravel, and waste.

3.Robust Structure for Long Service Life

Manufactured from high-strength structural steel and wear-resistant plates, the grab bucket offers superior resistance to impact, abrasion, and fatigue in harsh working environments.

4.Precise Control & High Efficiency

Smooth opening and closing actions enable accurate loading and unloading, reducing spillage and improving single-cycle handling capacity.

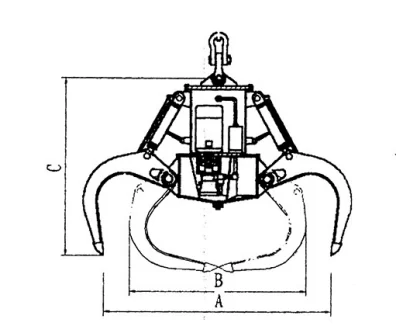

A hydraulic grab bucket is an efficient and reliable lifting attachment designed for handling bulk materials. Powered by a hydraulic system, it opens and closes automatically, allowing fast grabbing, lifting, and unloading of various loose materials. With strong grabbing force, stable operation, durable construction, and precise control, it significantly improves material handling efficiency and is widely used across a range of industrial applications.