1.Multi-tine structure for higher grabbing efficiency

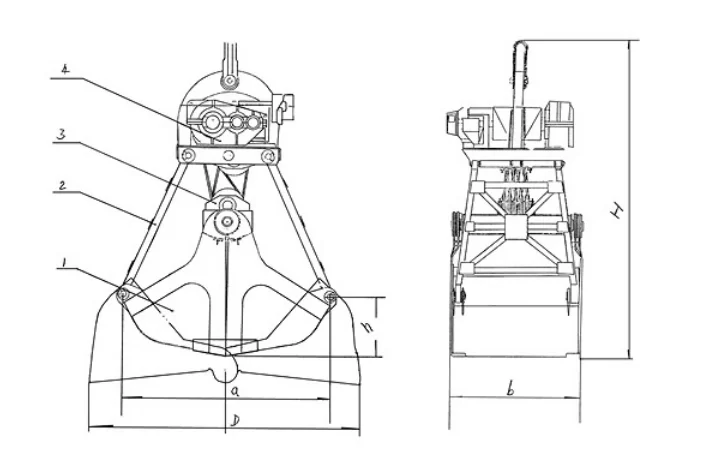

The crane orange peel grab features a 4–8 tine design that forms an enveloping grip when closed, enabling deep penetration into material piles. It is well suited for irregular materials with varying particle sizes, effectively reducing spillage and empty grabs while improving single-cycle load capacity and operating efficiency.

2.Strong adaptability to demanding materials and conditions

The grab reliably handles high-impact, high-abrasion materials such as scrap steel, ore, construction waste, and industrial solid waste. It maintains stable performance under frequent start-stop and continuous operation, making it ideal for ports, steel plants, mining, and solid waste handling.

3.Robust, wear-resistant structure with high reliability

Manufactured from high-strength alloy steel or wear-resistant steel plates, the grab features reinforced load-bearing areas and wear-resistant pins and joints. This design enhances impact and fatigue resistance, extends service life, and reduces maintenance costs.

4.Flexible drive options and smooth operation

Mechanical, electric, or electro-hydraulic drive systems can be selected to suit crane configurations and site requirements. The tines open and close smoothly and synchronously, minimizing crane impact and ensuring safe, reliable operation.

The crane orange peel grab is specifically designed for irregular bulk materials and heavy-duty working conditions. Its multi-tine structure greatly enhances material containment and grabbing efficiency. Built with high-strength, wear-resistant materials, it offers a robust and reliable structure suitable for long-term, high-frequency operation. With multiple drive configuration options, it can be flexibly matched with different crane systems and is widely applied in ports, mines, steel plants, and solid waste handling industries.