Crane Couplings

Hanko Crane Couplings - Your Reliable Crane Coupling Manufacturer in China

The crane coupling is a critical mechanical component used to connect two shafts, allowing them to rotate together and transmit motion and torque efficiently. It also serves to buffer, dampen vibrations, and enhance the dynamic performance of the shaft system, particularly in high-speed, heavy-duty power transmission applications. The gear coupling typically consists of two parts—one for the driving shaft and one for the driven shaft—connecting various power sources such as motors and reducers with the working machinery.

Hanko Heavy Industry manufactures high-performance crane gear couplings, designed for use in demanding eot and gantry crane applications, using high-quality materials and precise CNC machining. These crane brake wheel couplings are engineered to withstand heavy-duty operations and provide long-lasting, reliable performance in overhead cranes, gantry cranes, and other heavy lifting systems.

Different Types of Hanko Crane Couplings

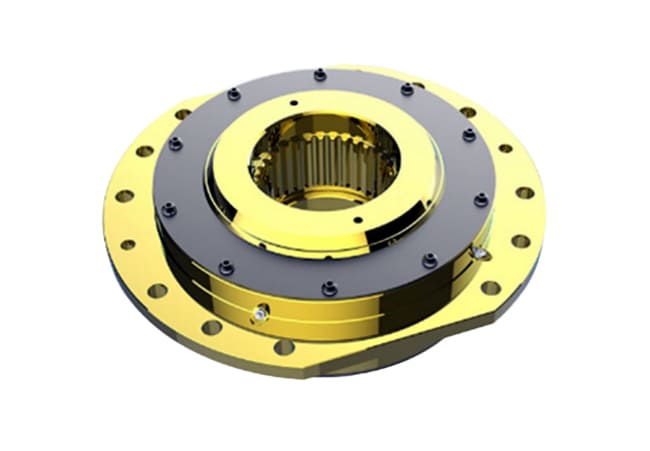

Crane Coupling

Crane couplings transmit torque smoothly between drive components, compensating misalignment, reducing vibration, and ensuring stable power transfer in heavy-duty crane operations.

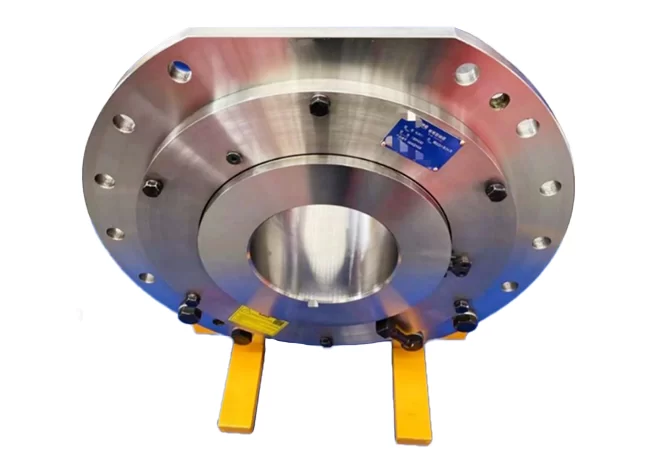

Brake Wheel Coupling

The brake wheel coupling connects driving and driven shafts while integrating a brake disc.

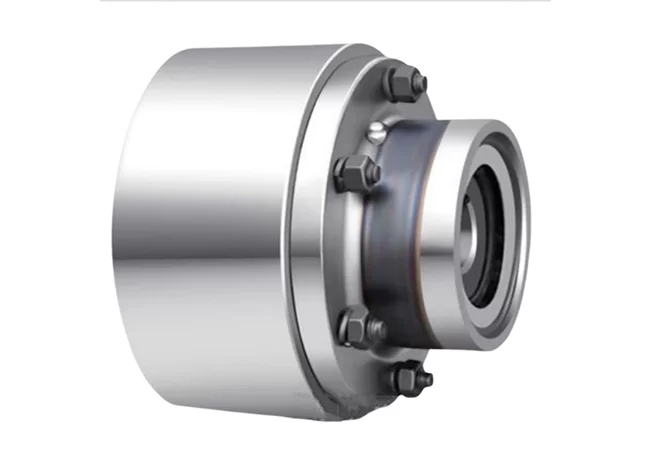

Gear Couplings

Gear couplings are designed for applications requiring reliable torque transmission under high load conditions.

Crane Brake Wheel Coupling

Crane brake wheel couplings combine braking and torque transmission functions, ensuring precise power control, reliable stopping, and stable operation in crane drive systems.

Crane Gear Couplings

Crane gear couplings provide high torque capacity, excellent misalignment compensation, and long service life, making them ideal for heavy-load and continuous crane applications.

Drum Gear Couplings

Drum gear couplings feature hardened gear teeth, high load capacity, and smooth torque transmission, ensuring reliable performance in demanding crane and hoisting systems.

Hanko Heavy Industry Crane Couplings Features

Crane Coupling Features

- High Load Capacity & Torque Transmission: Handles rated loads and overload impacts, ensuring reliable performance in demanding crane operations.

- Shock Absorption & Vibration Reduction: Minimizes impact and noise during motor startup and braking, enhancing system stability.

- Misalignment Compensation: Tolerates slight radial, axial, and angular misalignments, preventing damage to components.

- Safety & Durability: Sturdy design with no risk of failure, and protective covers for safe operation at high speeds.

- Easy Maintenance: Simple disassembly for easy replacement of wear components, ideal for crane maintenance cycles.

Crane Couplings Applications

Crane couplings are widely used in overhead cranes, gantry cranes, hoists, and material-handling systems to provide reliable torque transmission and reduce the risk of shock and wear. They are essential in industries such as steel mills, construction sites, ports, logistics centers, and manufacturing plants.

With their ability to connect motors, reducers, and other key components, crane couplings are crucial for heavy-duty operations, facilitating the continuous lifting, trolley travel, and precise load positioning required in demanding industrial environments.

Hanko Heavy Industry Crane Couplings

Crane Coupling

Drum Gear Coupling

Brake Wheel Drum Gear Coupling

Cardan Shaft Coupling

Flange coupling

Brake Wheel Coupling

Related Products

Crane Pulley Block

The Crane Pulley System uses several pulleys to distribute loads and change rope direction.

Forged Crane Hook

A forged crane hook is a key lifting component that ensures both operator and load safety.

Overhead Crane Wheels

Overhead crane wheels are key components of the crane’s traveling mechanism.

Variable Frequency Motor

The variable frequency motor is a high-performance drive solution for cranes.

Crane Wire Rope Drum

The crane wire rope drum is a vital lifting component in crane systems. It winds and unwinds the steel rope to raise or lower loads safely and efficiently.

1.What is a crane coupling?

A crane coupling is a mechanical device used to connect two shafts, allowing them to transmit torque and motion. It is designed to handle high loads, absorb shock, and compensate for slight misalignments in crane systems.

2.What are the key benefits of using crane gear couplings?

Crane drum gear couplings offer high load capacity, shock absorption, vibration reduction, and misalignment compensation. They are durable, require minimal maintenance, and help extend the lifespan of your crane’s critical components.

3.Can crane brake wheel couplings handle misalignment?

Yes, crane gear couplings are designed to accommodate radial, axial, and angular misalignments, preventing damage to bearings and shafts during operation.

4.Are crane couplings easy to maintain?

Yes. They can be quickly disassembled, and components like elastic elements can be replaced as needed, making them ideal for crane systems with regular maintenance cycles.

5.How do I choose the right crane gear coupling for my crane?

The choice of crane brake wheel coupling depends on factors such as load capacity, torque requirements, operating conditions, and shaft misalignment. Consult with our experts to help you select the right type based on your specific crane application.

6.What materials are used in crane couplings?

Crane gear couplings are typically made from high-strength materials like forged alloy steel, which provide excellent wear resistance and durability, ensuring reliable operation in heavy-duty environments.

7.Do you support OEM or custom crane brake wheel coupling solutions?

Yes, we offer customized gear couplings in different sizes, torque ratings, and surface treatments according to customer requirements.