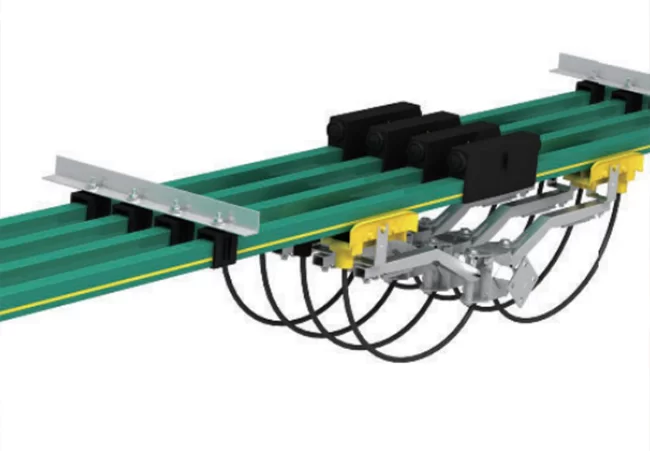

1.Stable Power Transmission: Provides uninterrupted current flow for cranes, minimizing downtime and energy loss.

2.High Safety Standards: Features insulation and protective covers to prevent accidental contact and ensure operator safety.

3.Durable and Low-Maintenance: Constructed with high-quality conductive materials and corrosion-resistant housing, offering long service life with minimal upkeep.

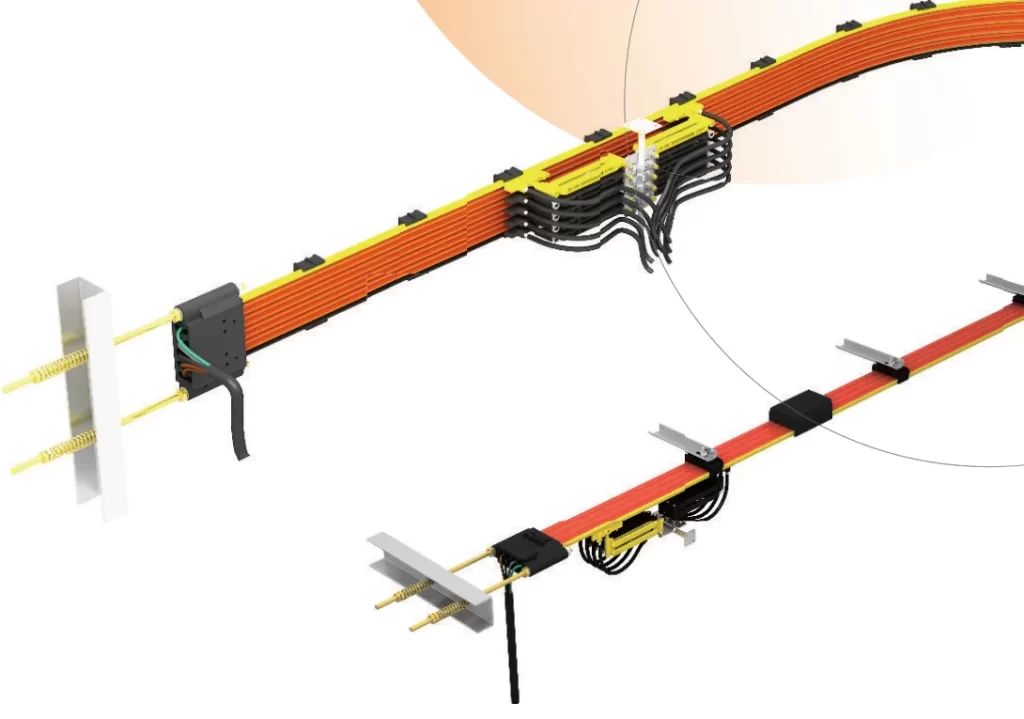

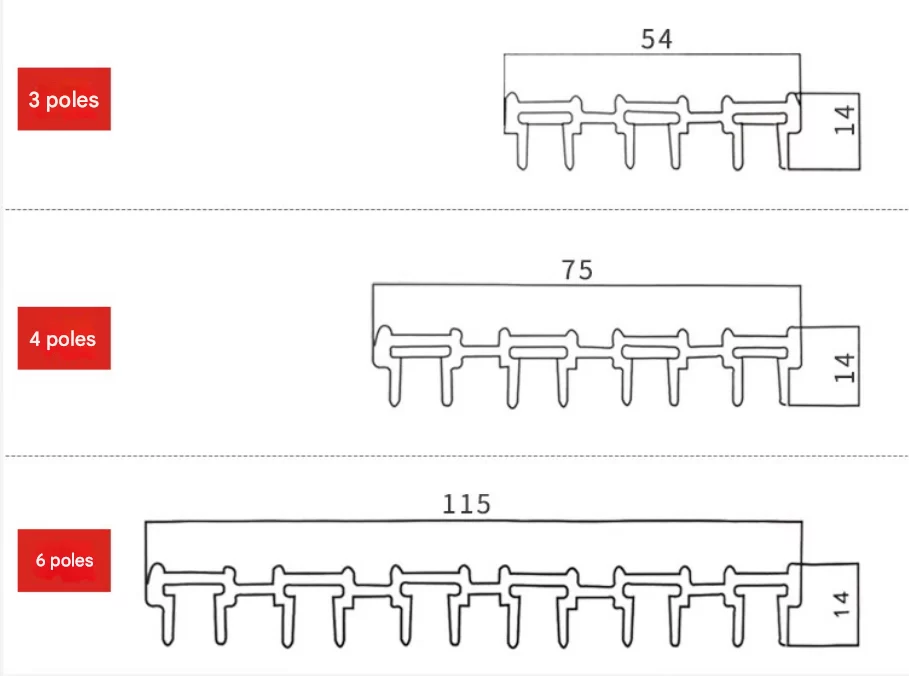

4.Flexible Modular Design: Easy to assemble, extend, or replace, making it suitable for various crane types and working environments.

The Overhead Crane Busbar delivers safe, efficient, and durable power transmission for crane operations. With strong insulation, stable conductivity, and a user-friendly modular design, it minimizes downtime and ensures long-term reliability. This system is widely trusted in heavy industry for its performance and cost-effectiveness.