Crane Brakes

Hanko Crane Brakes - Your Reliable Crane Brake Manufacturer in China

Crane brakes are a critical safety component used in overhead cranes, gantry cranes, and tower cranes. They consist of brake discs/pads, springs, pushers, levers, and adjustment mechanisms, integrated with the crane’s hoisting, trolley, and travel systems to regulate motion and secure loads.

Hanko Heavy Industry manufactures high-performance crane hoist brakes using premium friction materials and precision machining processes, combined with advanced heat treatment technology. This ensures exceptional braking torque, wear resistance, and structural stability. Each crane brake system features a compact design and long service life, optimized for seamless integration with various crane models.

Different Types of Hanko Crane Brakes

Crane Hoist Brake

The crane hoist brake works with the hoist motor to control lifting and lowering motions.

Overhead Crane Hoist Brakes

The crane hoist brake works with the hoist motor to control lifting and lowering motions.

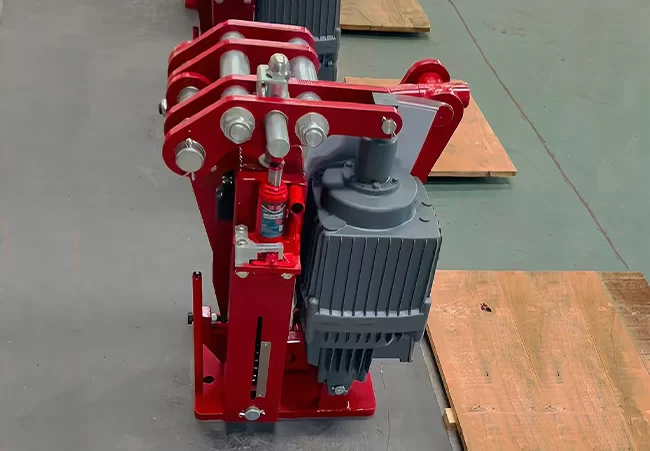

Gantry Crane Brakes

The gantry crane brake system works with the hoist and travel mechanisms to manage motion and prevent load drops.

Overhead Crane Brakes

Overhead crane brakes are critical safety devices for cranes. They control lifting and lowering operations, preventing accidental load movement.

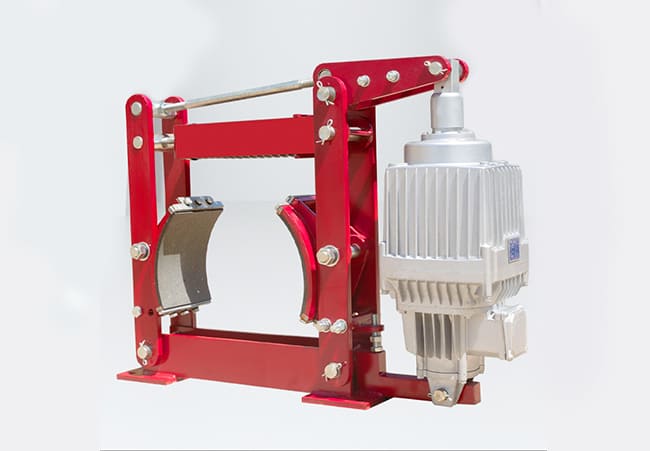

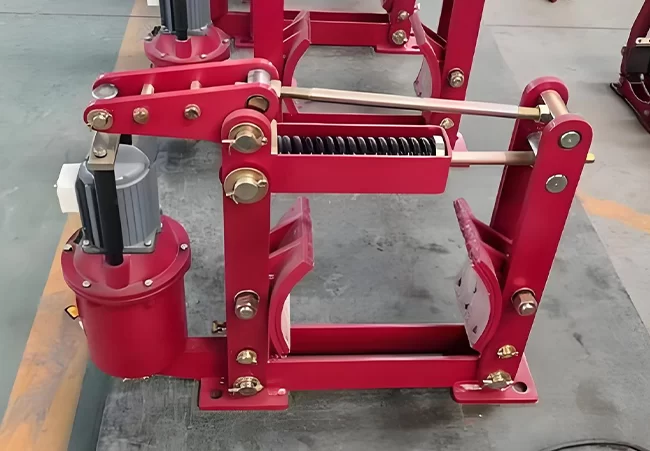

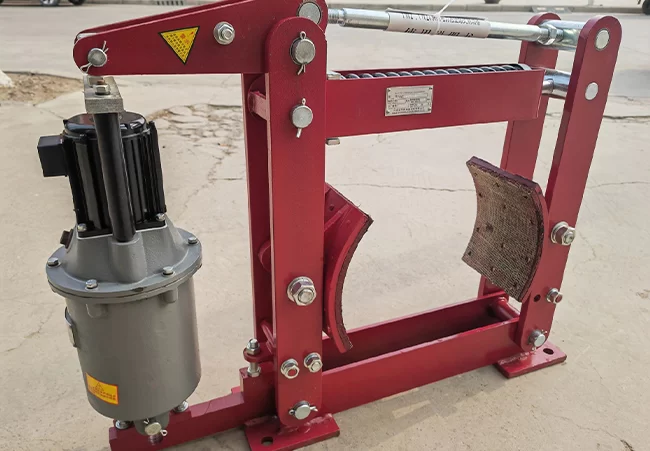

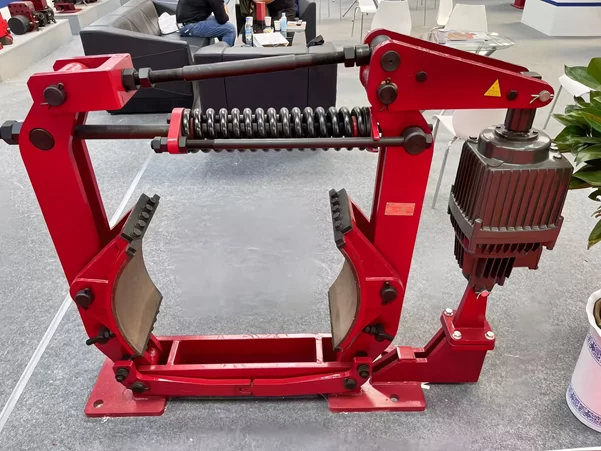

Crane Drum Brake

The crane drum brake is a core safety device in the crane hoist brake system. It controls the winding drum, ensuring stable stopping and holding during lifting and lowering.

Crane Brake Assembly

The crane brake assembly is a key safety component in crane hoist systems. It controls motion, holds suspended loads, and prevents accidents during lifting or lowering.

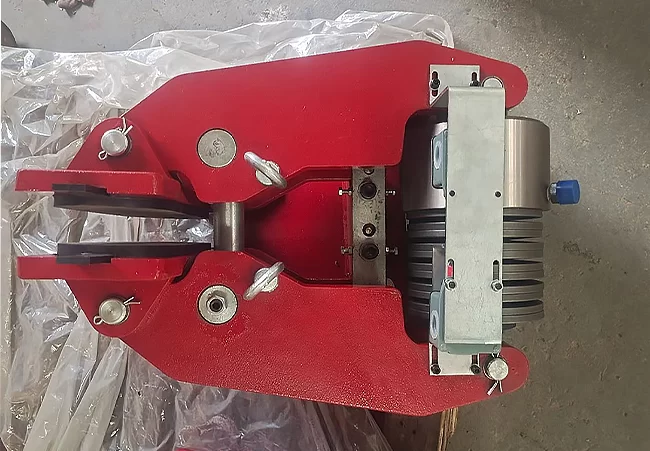

Crane Disc Brake

Crane disc brakes deliver fast response, stable braking torque, low wear, compact structure, and reliable performance, ensuring safe, precise control in heavy duty lifting applications.Overhead crane brakes are critical safety devices for cranes. They control lifting and lowering operations, preventing accidental load movement.

Crane Brake Drum

Crane brake drums provide durable friction surfaces, consistent torque transmission, strong heat dissipation, and long service life, supporting stable braking for demanding crane operations environments.

Overhead Crane Disc Brakes

Overhead crane disc brakes offer precise stopping, quick engagement, low maintenance, and high reliability, ensuring safe load handling during frequent starts and stops industrial operations.

Crane Hoist Brake System

Crane hoist brake systems integrate braking units, controls, and safety mechanisms, delivering stable stopping power, smooth operation, and enhanced protection for lifting equipment under load.

Crane Hoist Brake System

Crane hoist brake systems are engineered for precise load control, emergency stopping, low wear operation, and dependable performance across varied crane working conditions and environments.

Crane Hoist Drum Brake

Crane hoist drum brakes provide strong braking force, stable friction characteristics, simple maintenance, and long lifespan, supporting safe hoisting in industrial crane systems worldwide operations.

Overhead Crane Drum Brake

Overhead crane drum brakes ensure reliable braking torque, robust structure, effective heat resistance, and consistent performance, ideal for heavy duty and high inertia applications systems.

Hanko Heavy Industry Crane Brake Features

Crane Brake Features

- Safe and Reliable: Adopts advanced braking technology for fast response, high efficiency, and enhanced operational safety.

- Superior Stability: Crafted from high-quality materials with precision machining, offering excellent wear resistance and corrosion resistance for long-term stable operation.

- Long Service Life: Works seamlessly with premium motors and gearboxes to ensure an extended service life.

- Easy Maintenance: Features a simplified structure for convenient maintenance, significantly reducing equipment upkeep costs.

Crane Brake Applications

Crane brakes are indispensable safety components in diverse lifting operations across construction, manufacturing, and shipping industries. They are widely integrated into overhead cranes, gantry cranes, and tower cranes to ensure precise load control and safe operation during lifting, lowering, and positioning.

The rugged construction of crane brakes make them ideal for applications requiring responsive stopping, secure load holding, and emergency protection in heavy-duty environments. Whether in construction sites handling bulky materials or logistics hubs managing frequent cargo transfers, crane brakes enable efficient, accident-free material handling.

Hanko Heavy Industry Crane Brakes

Crane Brake

Crane Hoist Brake

Gantry Crane Brakes

Overhead Crane Brakes

Crane Disc Brake

Crane Drum Brake

Related Products

Crane Pulley Block

The Crane Pulley System uses several pulleys to distribute loads and change rope direction.

Forged Crane Hook

A forged crane hook is a key lifting component that ensures both operator and load safety.

Overhead Crane Wheels

Overhead crane wheels are key components of the crane’s traveling mechanism.

Variable Frequency Motor

The variable frequency motor is a high-performance drive solution for cranes.

Crane Wire Rope Drum

The crane wire rope drum is a vital lifting component in crane systems. It winds and unwinds the steel rope to raise or lower loads safely and efficiently.

1.What types of crane brakes do you offer?

We supply a full range of crane brakes, including electromagnetic, hydraulic, and drum brakes, suitable for overhead cranes, gantry cranes, and hoists.

2.How do I know which brake type fits my crane?

You can share your crane model, lifting capacity, and operation environment. Our engineers will recommend the right brake type and model for safe and efficient performance.

3.Are your crane brake assemblies compatible with major crane brands?

Yes, our brakes are designed to fit most international crane systems and can be customized for specific brands or dimensions.

4.What standards do your crane hoist brakes comply with?

All our brakes follow ISO and CE standards and undergo strict quality control tests, including torque testing and dynamic balance checks.

5.Do you provide installation and adjustment guidance?

Yes, we supply detailed manuals and offer technical support for installation, setup, and drum brake adjustment to ensure proper operation.

6.Do you offer spare parts and maintenance support?

Yes, we provide replacement parts, maintenance kits, and ongoing technical support to extend your brake system’s lifespan and reliability.