Crane Gearboxes

Hanko Crane Gearboxes - Your Reliable Crane Gearbox Manufacturer in China

The crane gearbox is a key power-transmission component used in overhead cranes, gantry cranes, and hoisting systems. It converts the motor’s high-speed rotation into low-speed, high-torque output, ensuring smooth, stable, and safe lifting operations. A gearbox typically includes hardened gears, shafts, bearings, and a durable housing designed to handle continuous heavy-duty work.

Hanko Heavy Industry manufactures high-strength crane gearboxes, overhead crane gearboxes, and gantry crane gearboxes through advanced gear cutting, heat treatment, and CNC machining. These processes deliver excellent torque capacity, low noise, and long service life. With compact designs and multiple reduction ratios available, Hanko crane reducers provide reliable performance for demanding lifting applications.

Different Types of Hanko Crane Gearboxes

Geared Motor

Geared motors combine electric motors with precision gearboxes, delivering controlled speed, high torque output, compact design, and reliable performance for industrial transmission applications.

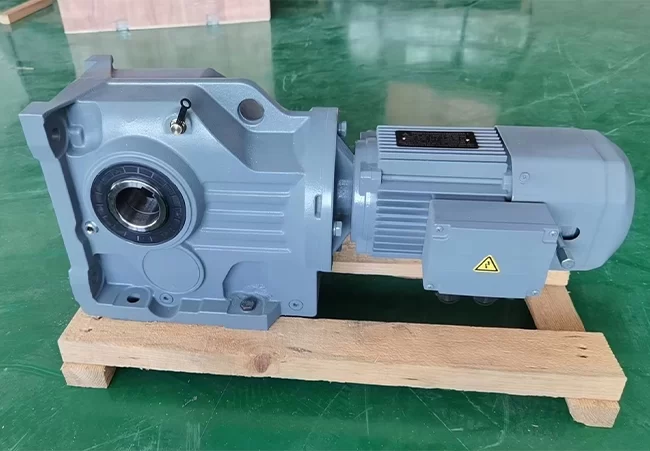

Crane Gearmotor

Crane gearmotors are designed for lifting equipment, providing high torque, stable operation, shock resistance, and precise speed control under heavy load working conditions.

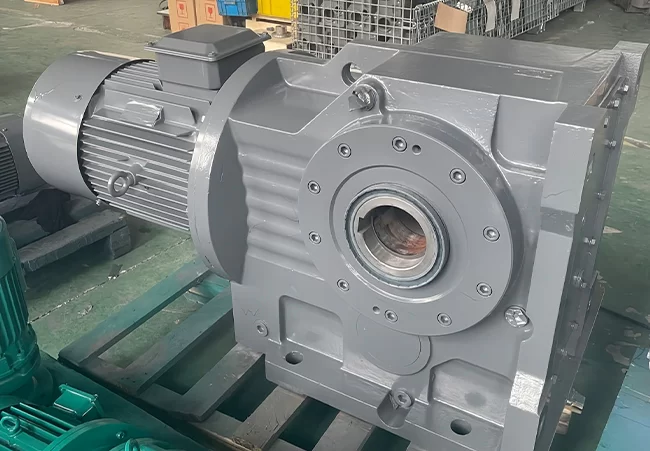

Reducer Motor

Reducer motors integrate a motor and speed reducer, ensuring efficient power transmission, reduced speed, increased torque, and long service life in demanding industrial environments.

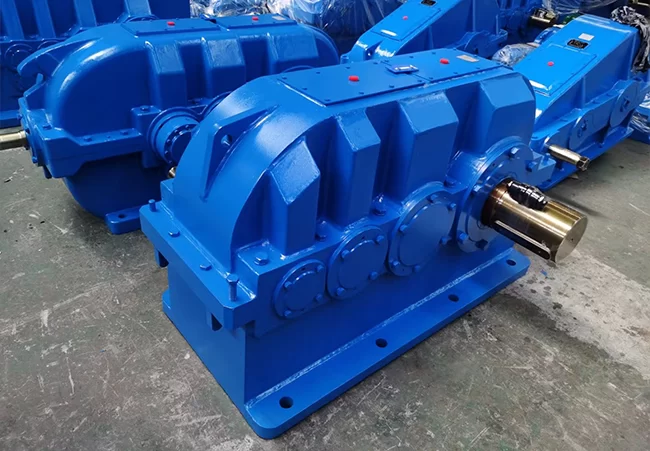

Crane Reducer

Crane reducers are engineered to withstand heavy loads, frequent starts, and harsh conditions, delivering stable torque transmission, high efficiency, and extended operational reliability.

Motor Reducer

Motor reducers offer compact integration, smooth power delivery, optimized speed reduction, enhanced torque output, and dependable operation for continuous duty mechanical drive systems.

Hanko Heavy Industry Crane Gearbox Features

Crane Gearbox Features

- High Load Capacity for Heavy-Duty Lifting: Carburized and quenched gears in crane gearboxes deliver strong load-bearing performance, ensuring stable operation under heavy crane workloads.

- Compact Design for Easy Installation: With the same load capacity, these speed reducers offer a smaller footprint and lighter weight—ideal for cranes with limited installation space.

- Smooth Operation with Low Noise: Precision-ground gears in crane gearmotors improve transmission efficiency, reduce vibration, and minimize noise for a safer and more comfortable working environment.

- Long Oil Change Interval & Lower Maintenance Cost: Designed for extended lubrication cycles, helping reduce downtime and overall maintenance expenses while increasing crane gearbox lifespan.

Crane Gearbox Applications

Crane gearboxes are widely used in overhead cranes, gantry cranes, hoists, and material-handling systems to provide stable torque and precise speed control. They ensure safe and efficient lifting in steel mills, construction sites, ports, logistics centers, and manufacturing plants.

With high torque output and reliable performance, crane gear reducers are essential for heavy-duty operations, helping cranes handle continuous lifting, trolley travel, and long-term load positioning.

Hanko Heavy Industry Crane Gearboxes

Crane Gearbox

Crane Hoist Gearbox

Overhead Crane Gearbox

Gantry Crane Gearbox

Geared Motor

Motor Reducer

Related Products

Crane Pulley Block

The Crane Pulley System uses several pulleys to distribute loads and change rope direction.

Forged Crane Hook

A forged crane hook is a key lifting component that ensures both operator and load safety.

Overhead Crane Wheels

Overhead crane wheels are key components of the crane’s traveling mechanism.

Variable Frequency Motor

The variable frequency motor is a high-performance drive solution for cranes.

Crane Wire Rope Drum

The crane wire rope drum is a vital lifting component in crane systems. It winds and unwinds the steel rope to raise or lower loads safely and efficiently.

1.What factors affect the lifespan of a crane gearbox?

Gearbox life mainly depends on load conditions, lubrication quality, working environment, and maintenance frequency. Regular oil changes and inspections of geared motors extend service life.

2.How do I know if my crane reducer needs replacement?

Unusual noise, increased vibration, overheating, oil leakage, or reduced lifting performance are common signs that the reducer may require repair or replacement.

3.Can your geared motors replace my old gearbox without modifying the crane?

Yes. We can match mounting size, shaft dimensions, gear ratio, and torque for notor reducers to ensure a direct-fit replacement.

4.Are your gearboxes suitable for harsh environments such as high temperature, dust, or outdoor use?

Yes. Our crane gearboxes include enhanced sealing, heat-resistant coatings, and customized protection options for heavy-duty or outdoor applications.

5.Can the gearbox operate continuously under high load?

Our crane hoist gearboxes are designed for heavy-duty and continuous working conditions. High-strength gears and precision machining ensure stable high-torque output.

6.Do you support OEM or custom gear reducer solutions?

Yes. We offer OEM and custom options for crane reducers , including torque, ratio, speed, and mounting customization.