1.Heavy-Load Power: Designed for crane duty with ≥0.95 power factor and overload up to 300% rated torque, ideal for frequent start-stops.

2.Intelligent Control: Variable frequency regulation (0.5–100Hz) cuts energy use by 25%.

3.All-Environment Ready: IP55 protection, Class F insulation, wide -25℃~60℃ range, salt spray and vibration tested.

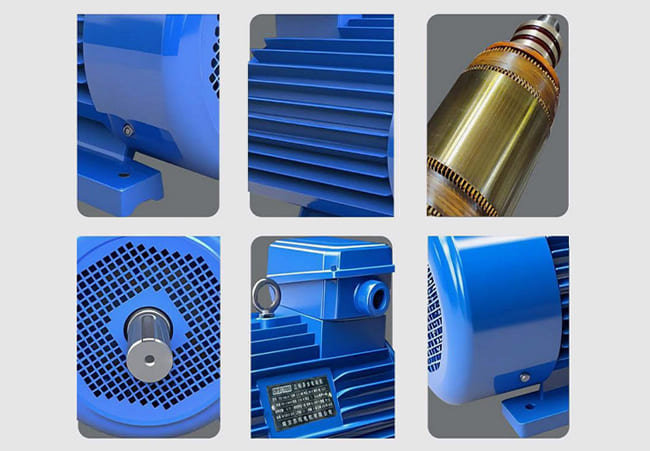

4.Long Service Life: SKF insulated bearings, vacuum impregnation, >100,000 hours design life.

5.Global Compliance: Meets IEC 60034 and GB/T 755, compatible with major-brand crane motor specifications.