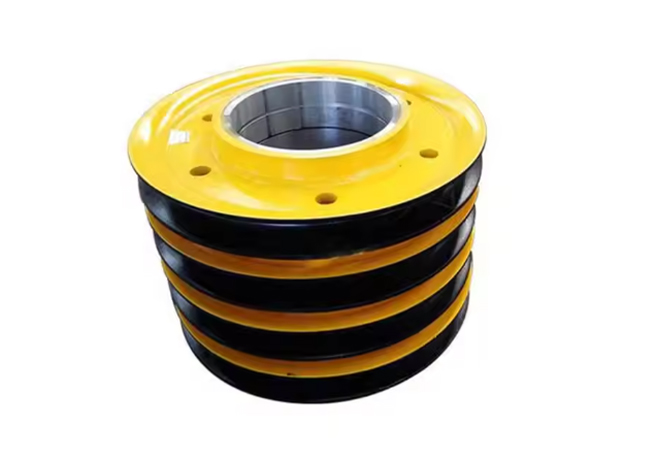

1.High-Strength Materials – The Crane Pulley System is made of premium alloy steel or ductile iron, giving strong load capacity and wear resistance.

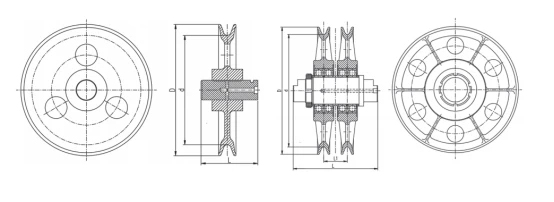

2.Precision Machining – Smooth grooves on every crane pulley wheel reduce wire rope wear and extend service life.

3.Flexible Adaptation – Multiple models of crane pulley blocks and simple crane pulley systems fit various crane types and lifting needs.

The Crane Pulley System from Hanko is built for high load, low wear, and steady performance. It meets the demands of frequent and heavy-duty lifting in overhead, gantry, and tower cranes.