What Is A Crane Hook?

The crane hook is a device used to grasp and lift loads through equipment such as hoists or cranes. It is usually equipped with a safety latches to prevent the lifting wire rope slings, chains or ropes connecting the load from detaching. The crane hook is a very crucial part of any lifting machinery, as it bears almost all the weight of the load. Any issues with it can lead to fatal accidents. Generally, standard crane hook assemblies follow a standardized manufacturing process.

At Hanko, crane hook production strictly adheres to technical specifications, utilizing premium materials and undergoing proper forging, machining, and heat treatment. This is our work—nothing extraordinary. What sets us apart is consistent quality. That’s why our hooks are used by many renowned crane manufacturers across China.

For export markets, custom-designed hooks are most common due to differing design standards. Our engineers stand ready to assist whenever you encounter challenges in hook design. We consider it an honor to offer our expertise—feel free to consult us anytime, absolutely free of charge.

Proper use and operation of crane hooks are crucial for maintaining their integrity and extending service life. Regular inspection and maintenance during daily use are essential for ensuring safety and optimal performance during lifting operations. Always adhere to the manufacturer’s guidelines and industry standards for inspection cycles and maintenance procedures. Additionally, replacing damaged or worn hooks is a critical aspect of crane hook safety and maintenance.

Hanko Heavy Industry will answer how many slings can be attached to a crane hook and provide a guide to help you choose the right crane hook for your needs. Whether you’re an experienced crane operator or new to the industry, this comprehensive guide offers valuable insights and deepens your understanding of crane with hooks used in construction.

How Many Slings Can Be Attached to a Crane Hook?

You need to know how many slings can be attached to a crane hook before starting any lift. Industry standards give you clear guidance. Most regulations state that you should attach no more than two slings directly to a single hook.

When using two slings, ensure the following:

1) The slings are of equal length;

2) If slings have different safe working load ratings, the load capacity is is related to the least safe working load;

3) The attachment points of a two-leg sling to the load are far enough apart to give stability without exceeding 90 degrees (Figure 1).

Why is it not recommended to connect multiple slings during hook operations? This relates to force distribution. When using multiple slings, the angle between the slings and the horizontal plane significantly affects the actual tension. If the angle is too small (e.g., horizontal angle less than 30°), the tension on the slings will far exceed their static load capacity. Uneven force distribution or differing angles among multiple slings can cause excessive tension on a single sling or one side of the slings. This rule helps maintain load balance, reducing the risk of slippage or overload. If your lifting operation requires more than two slings, we recommend using a pulley block to safely distribute the load.

Lifting hooks play a critical role across numerous industries, providing a safe and efficient means for hoisting and moving heavy objects. Whether you work in construction, manufacturing, or any field requiring material handling, understanding the various types of hooks and their specific applications is essential for ensuring safety and enhancing productivity. Next, Hanko will discuss how to select the appropriate crane hook for your needs.

How to Choose the Right Crane Hook

- Before selecting a crane hook, you must clearly understand the requirements of the lifting operation:

- Lifting Requirements: The maximum load capacity of the crane hook. Determine the required load capacity range based on the actual weight and dimensions of the items being transported. Additionally, consider the working class of the lifting equipment (e.g., M3, M4, etc.) to match it with an appropriate crane hook.

- Working Environment: The conditions and environment of the worksite dictate requirements for the crane hook. For instance, if operating in damp or corrosive environments, you may need hooks treated with anti-corrosion technology. Additionally, consider the impact of special conditions like temperature fluctuations or magnetic fields on the hook.

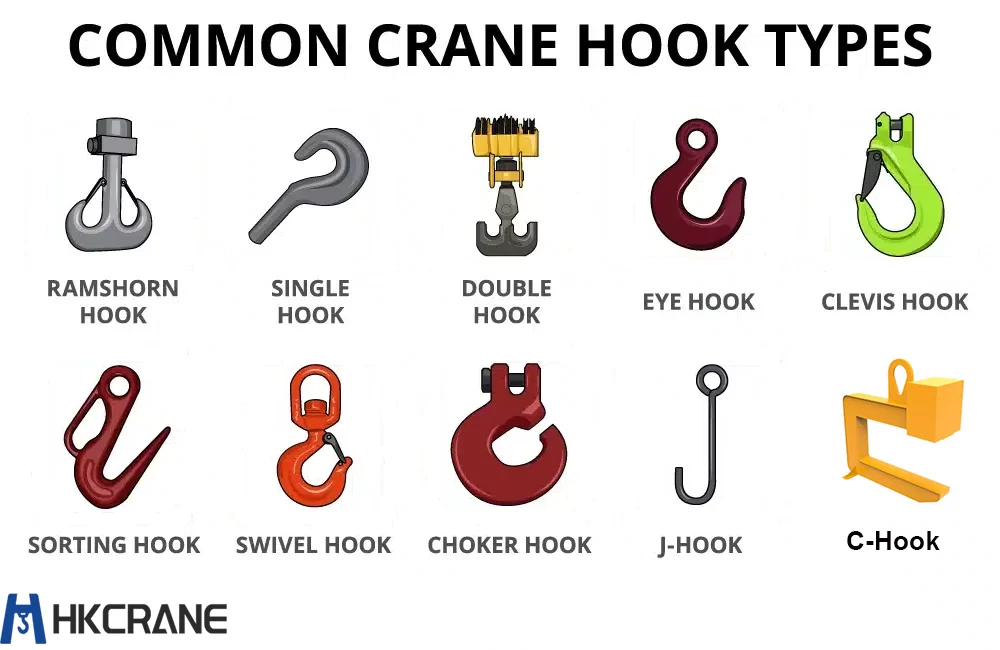

- Understand Different Types of Crane Hooks

- Ramshorn Hook: This type of hook is characterized by its double-horned shape, offering higher load capacity and increased stability. It is used in heavy-duty applications such as shipbuilding and steel structure fabrication.

- Single Hook: As the name suggests, this hook features a single lifting point.It is commonly used in lighter applications and where there is limited headroom. Single hooks are versatile and can be found in various industries, including construction, manufacturing, and maintenance.

- Double Hook: Featuring two lifting points, double hooks better distribute loads and enhance stability. They are often paired with another double hook for lifting long or large items like beams or girders.

- C-Hook: They are designed for lifting and handling heavy loads in industries such as steel mills, ports, and manufacturing facilities. These hooks are engineered to provide a safe and efficient method for lifting and moving large coils, slabs, and other heavy materials.

- Eye Hook: These are single-point hooks that are typically used in light-duty lifting. They feature an eye-shaped opening at one end, which is used to attach the hook to the lifting machinery.

- Clevis Hook: Clevis Hooks are similar to single hooks but feature a clevis pin instead of a latch. This type of hook is used mainly in industrial and manufacturing applications and is designed to handle high-capacity loads.

- Sorting Hook: These specialized hooks are designed to hang, sort, and store items in an orderly fashion. They are commonly used in warehouses and production facilities, where efficient and safe sorting of goods is essential.

- Swivel Hook: Swivel hooks are designed to rotate 360 degrees, offering greater flexibility and maneuverability during lifting operations. These hooks are often used in tandem with other hooks to provide additional stability and prevent accidental slippage.

- Choker Hook: Choker hooks are designed to grip and lift objects securely. They are also usually used in tandem with other hooks and are suitable for various lifting operations, from small-scale projects to large-scale industrial applications.

- J-Hook: J-hooks are used to lift flat or round objects, featuring a “J”-shaped hook that slides under the load. They are commonly used in construction and maintenance applications.

- Consider Safety Factors and Quality Assurance

- Safety Factors: Ensure selected crane hooks undergo rigorous quality inspections and comply with international and local safety standards and regulations. Hooks manufactured by Hanko Heavy Industry guarantee compliance with international safety standards such as DIN 15401/15402, ISO 2415, and ASME B30.10.

- Quality Assurance: Purchase crane hooks from reputable, certified suppliers or manufacturers to guarantee product quality and reliability. Review their certification credentials, customer reviews, and after-sales support to obtain reliable quality assurance—all of which Hanko can fulfill.

- Select Appropriate Additional Features and Accessories

Based on your specific requirements, consider crane hooks with additional features and crane hook parts to enhance operational efficiency and safety. For instance, some hooks incorporate sensors and telemetry technology to monitor load status and safety. Additionally, crane hook parts like triggers, locking mechanisms, or swivel rings can improve operational convenience and functionality.

- Select Based on Application

Different industries and lifting tasks may require specific hook types:

- Construction & Manufacturing: Eye hooks or self-locking hooks.

- Steel Mills or Foundries: Heat-resistant hooks with specialized coatings.

- Ports and Shipyards: Heavy-duty ramshorn hooks or double hooks.

- Automated Cranes: Automatic hooks with remote control and safety features.

- Never Forget Inspection and Maintenance

Even the best crane hooks require regular checks for wear, cracks, or deformation. Always adhere to a maintenance schedule to ensure ongoing safety and performance.

Choosing the right crane hook involves more than choosing the strongest option—it requires evaluating load, environment, usage, and your operation’s safety requirements. Investing in high-quality, appropriately matched hooks not only ensures safety but also enhances lifting efficiency and reduces downtime. If you require any type of hook, contact us for tailored advice and customized solutions.